aerospace_achievements

Some of our achievements

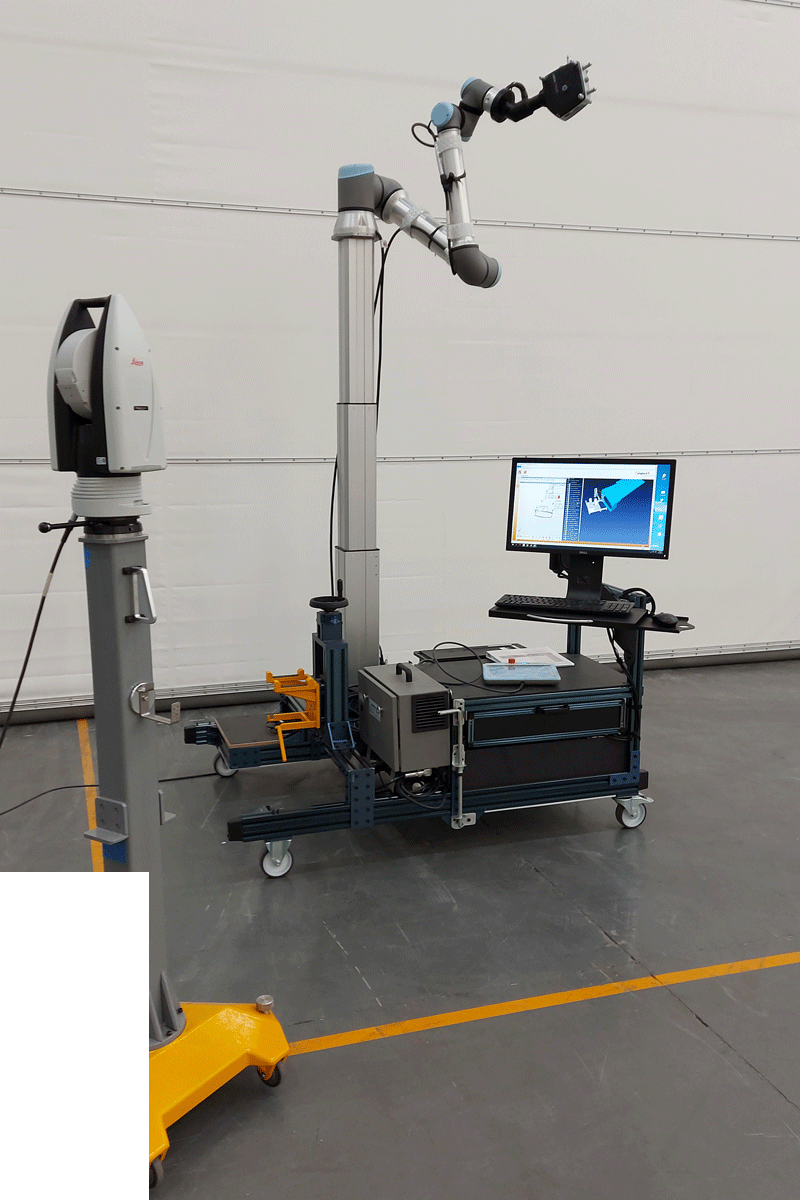

Automation : 3D scan wheel cart

Junction surfaces of fuse and wings are automatically 3D scanned by a laser tracker and Tscan 5 on a cobot and wheel car. Scans are then virtually aligned to verify the requirements of gap & collisions as well as wing locations to the fuse. Virtual fit are automated to optimize all the engineering requirement. Then, shims are tailor-made to fill the evolutive gap resulting from the virtual assembly.

Gains

- production lead time

- quality & repeatability on alignments

- remove human interventions and dependency

- Solution can be used for other metrology purpose as well

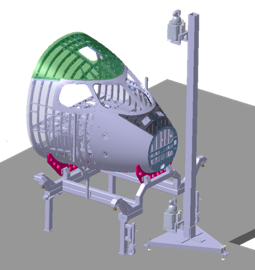

Automated inspection of aircraft components

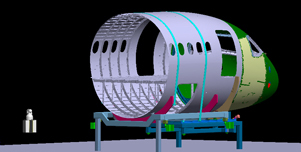

A turnkey system was used to perform the automatic inspection of specific airplane sub-sections (cockpit, forward fuselage, aft fuselage). The desired objective was to improve the precision of the final product and reduce the inspection time during production.

The system consisted of a laser radar, targets, and several interface tools. The automation performs precise measurement of the references and the key characteristics of the component, and generates electronic reports, presenting an analysis of the GD&T requirements. This project involved the development of an HMI (human-machine interface) which takes control of the application’s requirements, and includes customized software to automate the system.

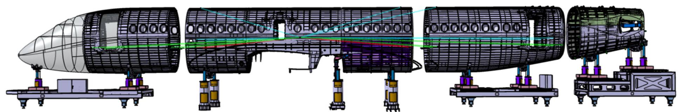

Assembly and adjustment of aircraft components

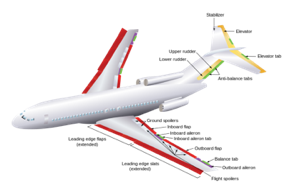

Large-scale metrology systems were integrated into various aircraft production lines, in order to revolutionize the assembly and adjustment methods for its principal components:

- Real-time assembly of the fuselage sections and joining of the wings to the fuselage

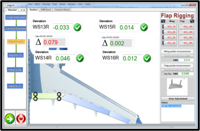

- Real-time adjustment of the flaps and the flight control surfaces (ailerons, elevators, and rudder), to the neutral and deflected positions

- Aircraft leveling

- Aircraft symmetry check

The iGPS system and the laser tracker are perfectly suited to the requirements of these applications. The use of one technology over the other depends mainly on the nature of the application, on the chosen methodology, the volume of the workspace, the environmental constraints and the required tolerance. Simulation tools allow us to determine the ideal number of instruments and their optimal position in the work area, in order to minimize the cost without affecting the uncertainty of the measurement.

A user interface is developed for each application to guide the operator through all the measurements. The collected data is treated and can be used to define the references, compare the measured model with the theoretical model, align or orient the parts, or calculate the parameters to ensure that they conform to the client’s requirements.