Heavy industry, a major challenge for dimensional measurement!

Heavy industries operate on imposing scales, while demanding precision to a fraction of an inch

Amrikart is there when heavy industries need high precision. High precision industrial surveying is one of our specialties.

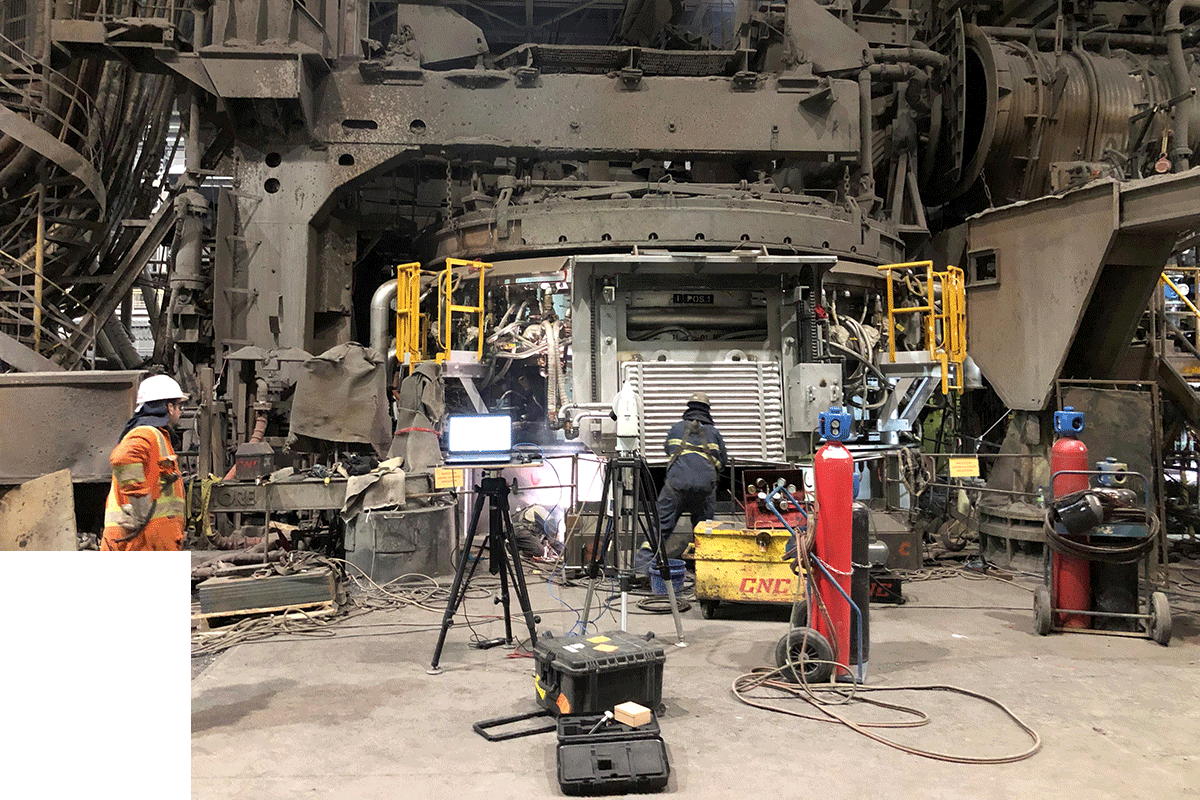

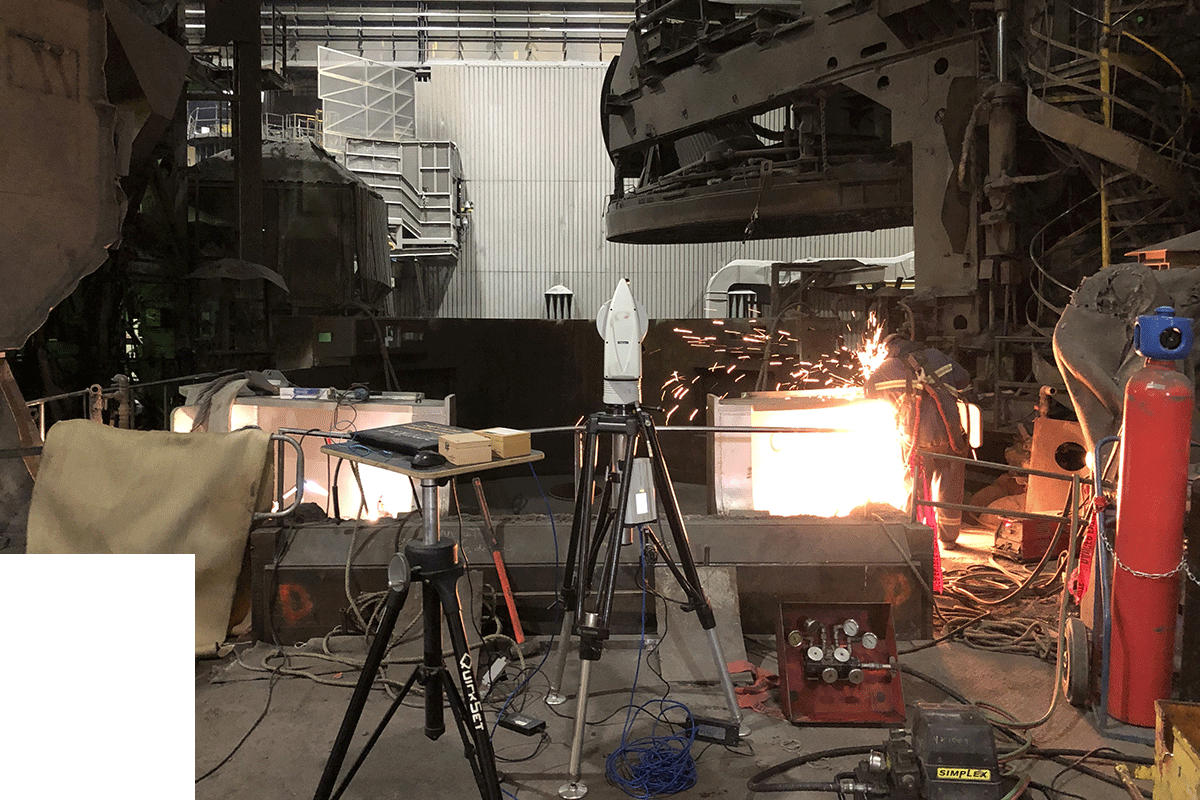

Wether for mines, dams, steel and aluminum plants, cement plants, mining and processing minerals, chemical industries, Amrikart has the portable instruments along with the expertise to ensure the most precise measurements and alignments.

We work in any kind of environment and ensure the highest possible accuracy.

Some of our achievements:

- Roller alignments and machinery : molds | robots | complete structures

- Furnace inspection and alignments – monitoring the condition of the bricks | rolling-furnace gear inspections | Furnace replacement

- Alignment of motors-generators: verification of support bases | rotors-stators alignments | bearing cage and support block alignments | 3D scan and reverse-engineering of casings | flanges alignment

- Inspections and alignments of overhead cranes

- Rail leveling and alignment for CNC

- Assembly simulations with digital twin

- Alignments driven by 3D metrology

- Inspection of pipe interiors and wall thicknesses for abrasion monitoring

- Digitization and reverse engineering of existing machines or surrounding environment

AMRIKART : ESSENTIAL REFERENCE FOR CANADIAN STEEL PLANTS

| To read : 3D metrology supports Still Mill Electric-Arc Furnace Replacement |

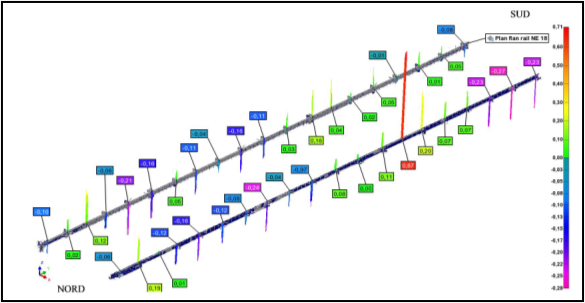

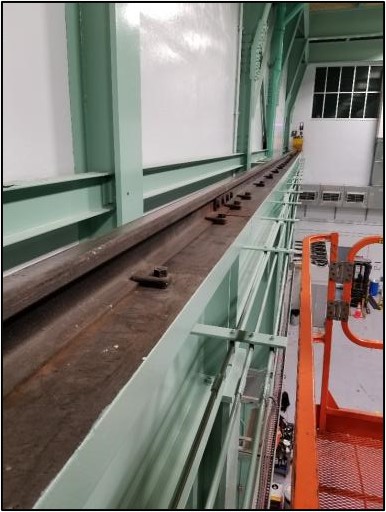

CRANES

Amrikart inspect your cranes and structures :

- Linearity and flatness of the rails

- Parallelism and rail location

- Rail shape

- Level

- Location and shape of the supporting pillars

- Deflection

We are there for your needs in Pulp and Paper industry

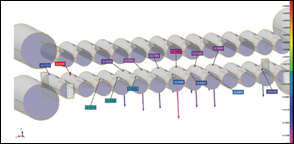

- Inspection and alignment of rolls in 6 degrees of freedom

- Alignment of drive shafts, motors and gearboxes

- Analysis of roller and contact surfaces by 3D scannings

- Inspection, levelling and alignment of machineries

- Installation and integration of new machines in existing production lines (upgrades, alignments...)

- Colision and gap analyzes

- Levelling, parallelism analyzes, positionning of cutting tools and conveyors

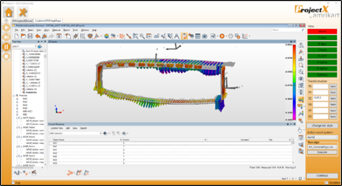

Assembly simulation by digital twin

Amrikart considerably reduces the installation time of machinery while ensurig a good assembly fit at first time through its assembly simulation method:

- Inspection of each component of the assembly, independantly

- Virtual simulation of the assembly with the measured data

- Determination of reworks, gaps and collisions + verification of engineering requirements of the virtual final assembly

- Rework of the components if necessary so that the assembly will meet the requirements

- Live guidance of the final assembly to its best position determined by the virtual assembly.

- To know more, consult our page about predictive assembly

Considerable Gains :

- Time saving: no need to pre-assemble and disassemble to rework anymore, assembly right on first time. Faster production restart!

- Optimal and controlled quality : reworks are made directly where they are needed. They are all identified during virtual assembly and inspected before final assembly. Alignment is the best it can be.

- Virtual assembly ensures that the assembly will meet engineering requirements even before physically performing it

Assembly right the first time and guided live by 3D metrology, no more rework during assembly