Automated Solutions

AMRIKART SIMPLIFIES 3D METROLOGY TO AUTOMATE YOUR PRODUCTIONS

Turnkey Solutions

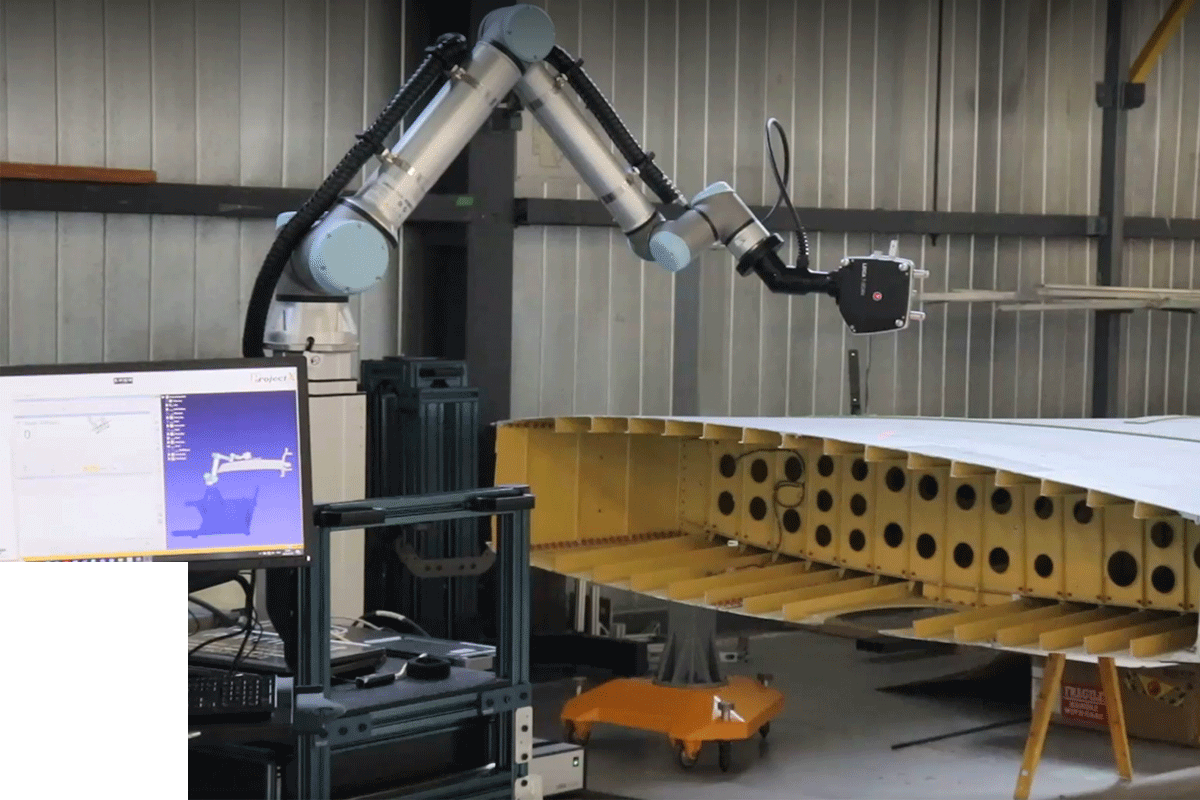

Amrikart carries out turnkey automation projects, integrating metrology solutions into production processes.

These comprehensive solutions include inspection, 3D scanning, alignment and metrology data management systems fully integrated into production lines.

Our turnkey solutions include

- Needs analysis

- Consulting on the best solutions

- Design and imtegration of selected solution

- Open programming platform

- Customized software interfaces that can be modified directly by the customer

- Integration into your 4.0 manufacturing process

- Training and support of the applications

Read our article : Metrology drives Large Scale Assembly

AMRIKART AUTOMATES THE MOST ADAPTED MARKET TECHNOLOGIES TO YOUR NEEDS

INTEGRATING AND AUTOMATING 3D MEASUREMENT DATA:

ESSENTIAL FOR INDUSTRY 4.0

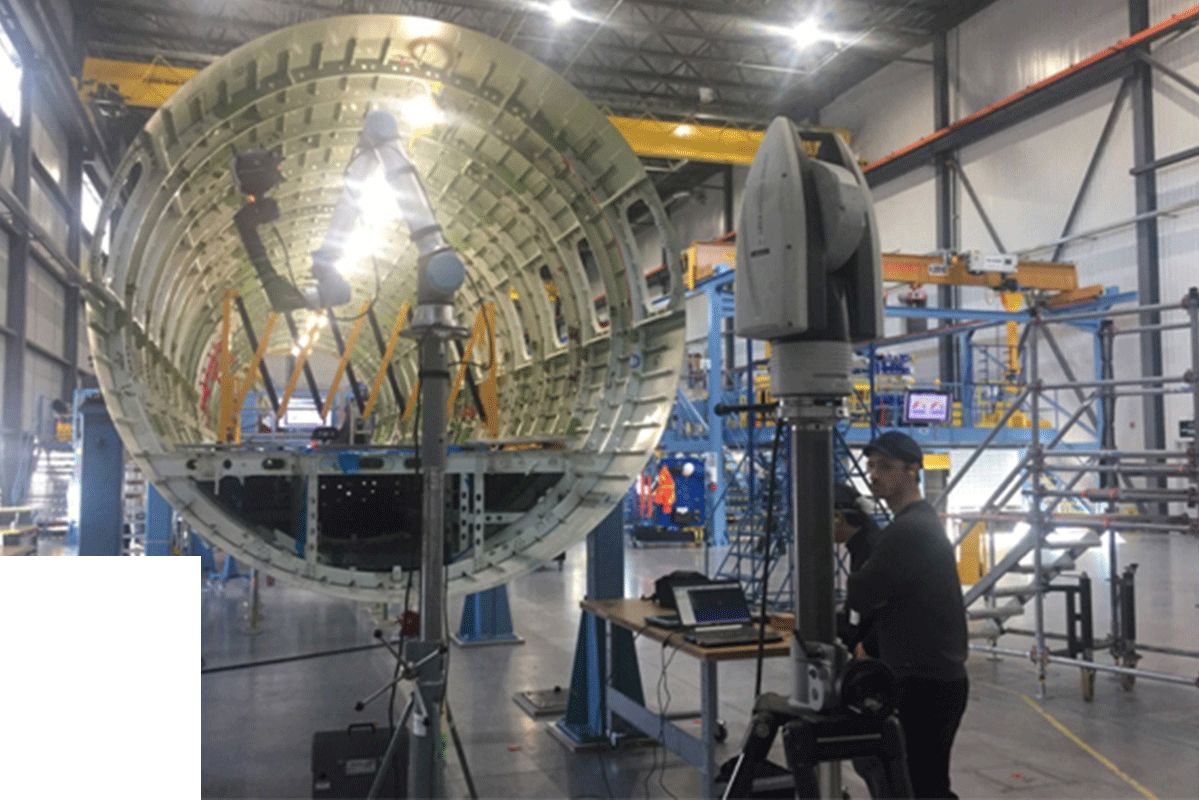

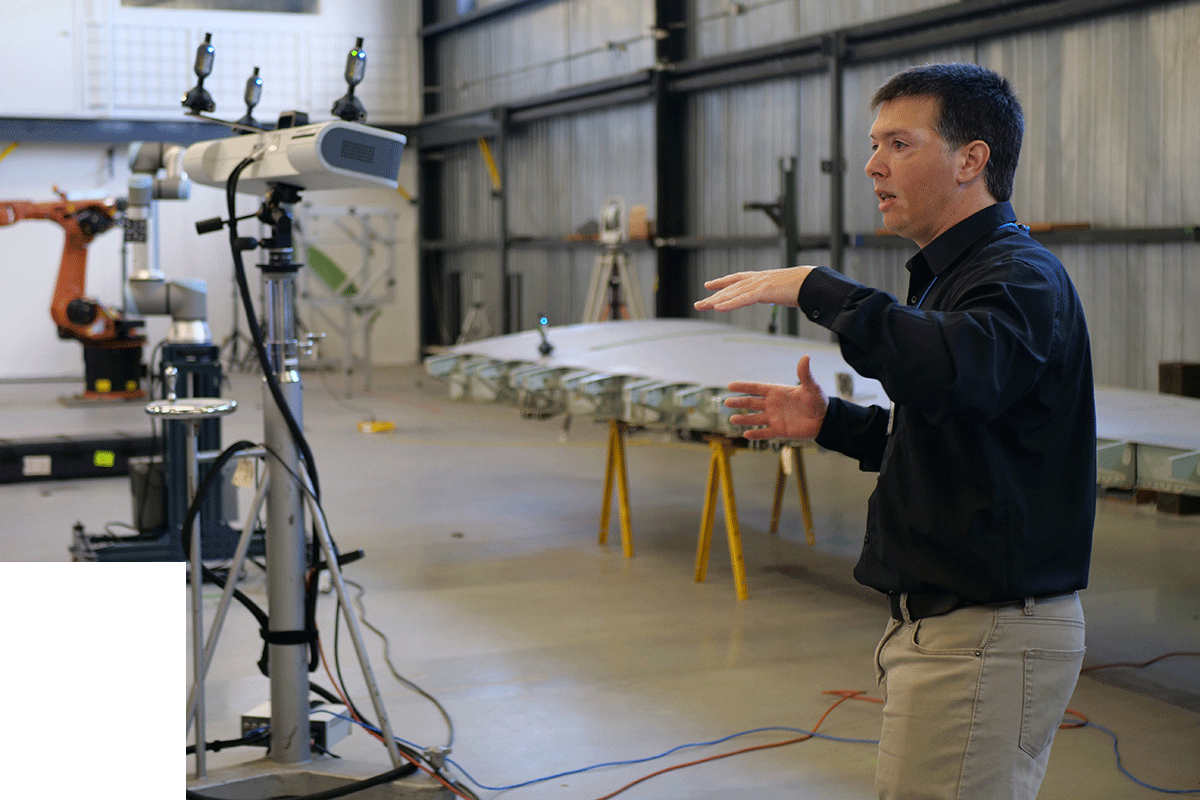

Integrators of iGPS solutions

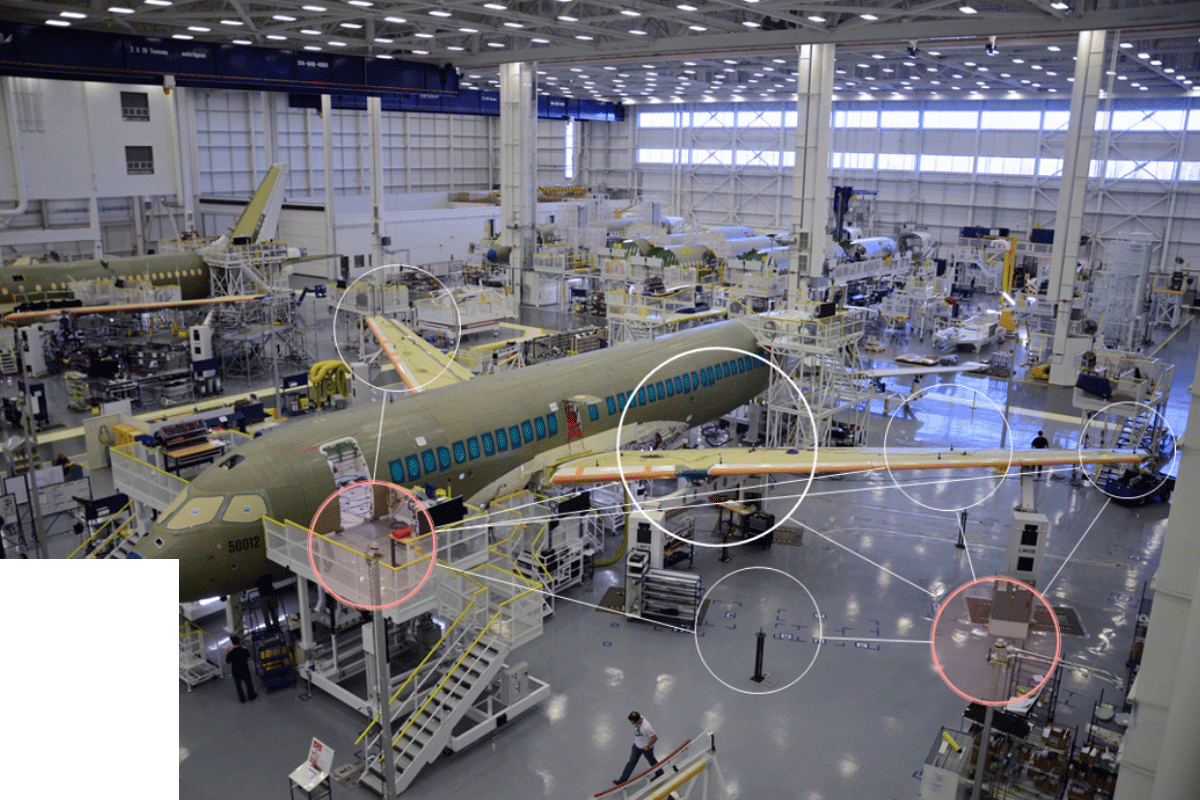

Amrikart stands out as a specialist in the iGPS (infrared Global Positioning System) system integrated into a production environment. This system allows the localization and tracking, at the scale of a complete factory, of multiple objects with metrology precision. IGPS technology is particularly applicable to manufacturing, assembly and quality control.

An iGPS network has unique advantages that would not be possible with other systems:

- Complete coverage of an unlimited work volume where each sensor position is known continuously and at a very high precision metrology level;

- Consistent accuracy throughout the measurement volume, typically 200µm (.008 ’’) at 95%;

- Modularity and flexibility: the number of “satellites” (transmitters) and “targets” (detectors), as well as the density and geometry of the network can be adapted to the dimensions of the workstation;

- Permanent self-monitoring to prevent any drift (automatic recalibration without operator intervention);

- Multi-user system allowing real-time applications in several independent cells with the same system, without loss of performance

The user interface supports the operator through every operation they need to perform, whether it is inspection or automated assembly.